What does a condensate pump do?

Condensate Pump

For HVAC or freezing processes, condensation must be drained from the building to the outside of the building to ensure proper drainage. The condensation process generally occurs when air flows through the cold evaporator coil during the cooling process. The refrigerator uses a condensate pump to pump the condensed water. A condensate pump is mainly a type of pump uses to collect the hot water as well as fluid generated due to the condensation method from the heating system. Here in this article, you’ll find What does a condensate pump do?

Therefore, the accumulated water in the spool drips onto the drain pan under the spool.

There is no need to use a pump in a system that can use gravity to drain the water that collects in the sump. However, air conditioners often need to use this pump to drain the water and prevent it from entering the room.

Condensate pumps used in residential complexes usually have low power (approx. 60 W) and are simple in functionality. However, it is essential to check this device regularly to prevent water from dripping on carpets, furniture, and appliances when you get home.

Features of Condensate Pump

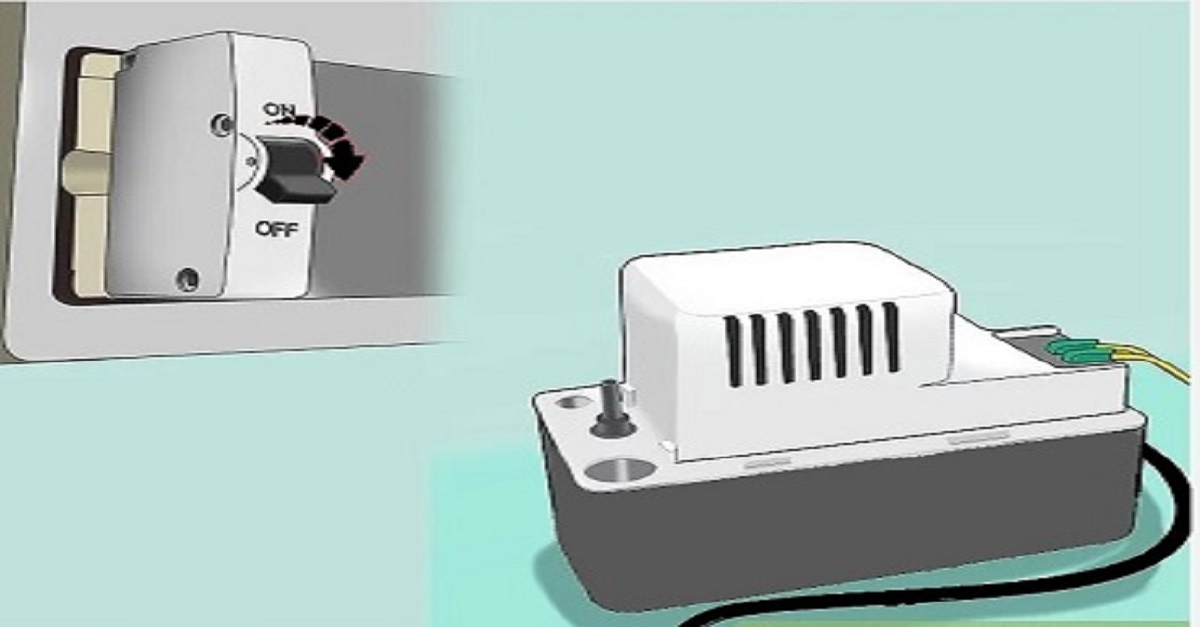

It is always a good idea to check that the air conditioning is working and using the pump. In general, condensate pumps have the following specifications and features that you should know about:

- Float switches are inputs that are used to supply power to the pump or otherwise. When the water in the tank reaches the level set by the float switch, the signal to operate the pump is activated until the water or liquid is significantly reduced. In this case, the pump will stop working.

- The pump’s fuel tank capacity is typically 0.5 to 1 gallon or 2 to 4 liters. Smaller pumps may not have a water tank but are placed directly in the drain pan to pump the condensate out of the pan.

What does a condensate pump do?

The standard condensate pump has two main functions: a motor and an impeller. The motor provides enough power to direct water through the condenser tube. Then connect the hose to the drain system or plunge pool.

Usually, the condenser pump does not work 100%. Many manufacturers have small built-in storage tanks (2 liters is common). When the water tank is filled to a certain level (set by the manufacturer), the pump starts to work.

The main reason to configure a pump this way is to save energy. The pump should only run for about 1 minute at a time instead of running continuously.

Choosing A Condensate Pump

The proper selection of the pump is very important for its working. It is very hard to choose the best condensate pump according to application. Before purchasing a condensate pump, consider the following:

- Pay attention to the UL and CSA markings on the pump. This certification is very important to ensure that the pump is designed and manufactured to industry standards.

- Thermal overload protection is an additional function that enables the pump motor to be switched off in the event of overheating, thus protecting the pump from damage and the risk of fire.

- If you need a storage tank, look for high-impact ABS tank materials and storage tanks with leak-proof and rust-proof designs.

- Stainless steel shafts extend the life of the pump.

- If the outlet line is higher than the tank, the removable check valve option prevents water from flowing back into the tank.

- The power cord and plug are the correct lengths for your application.

- The safety switch has good performance. In the event of an overflow, you can connect a safety switch to trigger an alarm. This output can also be used to turn off the air conditioning to prevent further damage to the system.

- In countries with temperate climates, especially in winter, it is necessary to remove altogether the condensate released by the pipeline. This is important because water that is not drained can freeze, causing pipes to burst and the system to malfunction.

Advantages of the Condensate Pump

The significant advantages of the condensate pump are given below:

- These pumps have the capability to pump the condensed fluids.

- The condensate pump has very high efficiency.

- These have float switches.

- They turn On and Off automatically.

- The condensate pumps have the capability to decrease bacterial contamination by sewage water.

- These types of pumps have a long service life

- They have high performance

- The condensate pump has top quality safety features

- They have the capability to deliver pulsating free flow of the water.

Disadvantages of the Condensate Pumps

The major disadvantages of the condensate pump are given below:

- They have priming problems.

- The condensate pump doesn’t have the self-priming capability.

- It has a high carbon footprint.

Applications of Condensate Pumps

The condensate pump has the following major and most common applications:

- These pumps use in refrigerators

- They use in the boilers

- They also use for various industrial applications