How to characterize nanoparticles?

A nanoparticle is actually a tiny particle that ranges between 1 to 100nm in size. They are undetectable by the human naked eye. Nanoparticles can exhibit meaningfully different physical and chemical properties to their larger material complements. In this article, we are going to discuss how to characterize nanoparticles and the most significant examples of metal nanoparticles.

Table of Contents

What are metal Nanoparticles?

Metal nanoparticles are submicron scale objects that are made up of pure metals e.g. platinum, gold, titanium, zinc, cerium, iron, and thallium or another compound such as oxides, sulfides, hydroxides, phosphates, fluorides, and chlorides. (here in this article, you will find the most significant examples of metal nano-particles like gold nano-particles, silver nano-particles, and titanium dioxide nan-particles)

The term metal nanoparticles can be used to describe nano-sized metals with dimensions in the range of 1 to 100nm. Some of the metal nanoparticles are useful for a variety of applications e.g. as catalysts, optics, electronics, biosensors as well as magnetics.

How to characterize nanoparticles?

Nanoparticles can be characterized in two ways.

- The first method includes methods intended at controlling the physical properties (such as size, shape, monodispersity, or crystal structure) of the nanoparticles themselves.

- Other characterization methods aim to determine the chemical properties of the particles. And also including the presence and binding methods of ligands or other conjugated molecules, and zeta potential.

- The characterization of nanoparticles is a vast and challenging subject. As new materials enter commercial applications from the discovery stage, the essential for repeatability and quality control continues to grow.

- Nanoparticles exist in various chemical components, from micelles to metals (oxides), from synthetic polymers to large biological molecules. Each of these materials has completely different chemical properties and can be analyzed using a variety of methods, including optical spectroscopy, X-ray fluorescence and absorbance, Raman spectroscopy, and solid-state NMR.

- However, the behavior of nanoparticles generally depends largely on their nanometer size. In this way, in the process of characterizing nanoparticles, studying size, shape, surface charge and porosity are the basic steps to fully understand and predict their behavior. This is how to characterize nanoparticles.

Nanoparticles characterization techniques

The techniques which are used for the characterization of nanoparticles are

- UV-Visible Spectroscopy,

- Transmission Electron Microscopy (TEM),

- Differential Centrifugal Sedimentation (DCS),

- Nanoparticle Tracking Analysis (NTA),

- Scanning Electron Microscopy (SEM), X-Ray Diffraction (XRD).

Transmission Electron Microscopy (TEM)

Transmission electron microscopy is undoubtedly one of the most important techniques for characterizing nanoparticles.

TEM uses an electron beam focused on a thin sample (usually less than 200nm) to produce micrographs of nanoscale materials with high lateral spatial resolution. Current electron microscopes can achieve resolutions as low as 0.05-0.1 nm by using deviation correctors to reduce image distortion, thereby providing high-resolution images with atomic resolution.

TEM also allows studying of the crystal structure of selected microscopic regions of crystalline material by spatially confining and focusing the occurrence ray and detecting the resulting electron diffraction pattern. With such high spatial resolution and selectivity, TEM makes it possible to study the size, shape, and structure of crystals at the individual particle level.

Once a representative image series of a nanoparticle sample is obtained, the individual sizes of approximately 1000 randomly selected nanoparticles should be measured to obtain meaningful statistics to determine the size distribution. The program can be executed manually (inherently affected by human error, prejudice, and subjectivity) or through automated particle analysis methods. This is how to characterize nanoparticles.

Although TEM allows visual inspection of individual particles with nanometer resolution, the entire sample preparation, measurement, and analysis workflow can be time-consuming.

Applications:

The nanoparticles must be transparent to electrons and capable to endure the high vacuum and electron beam energy used in the characterization process. Especially due to high-energy electron beams, sample damage is a known problem with organic, polymer, and hybrid nanoparticles.

This tricky situation can be solved by using Cryo-EM (see advanced methods) or by reducing the acceleration voltage, but at the cost of increasing the complexity of the measurement process or reducing the achievable resolution. Finally, TEM is a very expensive technology (purchase and maintenance costs) and requires very skilled employees.

Hope you will get how to characterize nanoparticles.

Metal nanoparticles examples:

Gold Nanoparticle:

- We use gold nanoparticles in varieties of chemical reactions.

- The gold nanoparticle’s surface can be used for selective oxidation. In specific cases, the surface can also reduce the reaction.

- They are being developed for numerous fuel cell applications.

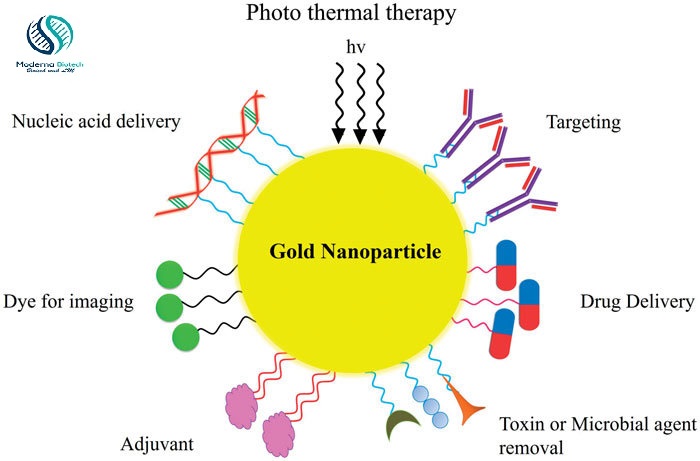

- Their optical-electronics properties are being discovered widely. And they have applications in high technology such as sensory probes, therapeutic drugs, electronic conductors, organic photovoltaic cells. The Gold nanoparticles also have their applications in drug delivery and catalysis.

- These nanoparticles can be used in different domain and it has important applications in the biomedical field. In addition, because of their large surface and the ability to be coated with a range of therapeutic agents, they have been exhibited a great potential to be used in drug delivery systems.

Silver Nanoparticle:

- Silver nanoparticles have unique properties that find countless applications such as anticancer, antimicrobial, catalytic, larvicidal, and wound healing.

- These are progressively used in numerous fields including food, medical, health care, consumer, and industrial purposes because of their unique chemical and physical properties. These may include electrical, optical, thermal, high electrical conductivity, and biological properties.

- Silver nanoparticles are mainly used in antimicrobial coatings, wound dressing, in many textiles, keyboards, and now biomedical devices have silver nanoparticles that continuously release low levels of silver ions to protect against bacteria.

- The silver nanoparticles have an antimicrobial effect. And because of this property, they can be in dental work, wound and burns treatment, surgery applications, and biomedical devices. It is also well known that silver ions are highly toxic to micro-organisms.

Titanium dioxide nanoparticle:

- The nanoparticles of titanium dioxides have a high reflective index and are bright. This makes them well suited for an industry dealing with pharmaceuticals, toothpaste, coating, inks, paper, food products, and textile.

- Ultrafine titanium dioxide is mainly used in construction and housing. These are used as an additive to plastics, paints, types of cement, tiles, windows, and other products for their ultraviolet absorption and photocatalytic sterilization properties e.g. in antifogging coating and self-cleaning windows

- Titanium dioxide is a great sunscreen active for redness-prone and sensitive skin. The reason is that they are inert earth minerals that are used as a thickening, lubricating, whitening, and sunscreen ingredients in cosmetics. And they also protect skin from harmful radiations and considered no risk of skin sensitivity.

- The nanoparticles of titanium dioxides have a wide range of applications. For example in reducing the toxicity of dyes and in pharmaceutical drugs, in wastewater treatment. And also in the reproduction of silkworm, in space applications, in food industries, etc. Therefore they have important applications in the industry. In addition, they also have advantages in the environment and agriculture.

See also nanocoating applications